For Milling Efficiency

Maxi-Mil is a powerful aid to milling efficiency, proven to lower manufacturing costs and produce better quality pellets when used as part of an Anitox milling efficiency program. Available with and without added mold control, Maxi-Mil products can reduce process loss and optimize feed moisture levels, improve mill throughput, reduce power consumption during pelleting, and improve pellet quality. By protecting feed nutritional values and pellet quality, Maxi-Mil helps optimize feed intake, driving efficient live production of poultry, swine and farmed fish.

To speak to one of our Maxi-Mil experts about producing better quality feeds more efficiently, contact us.

Suitable for:

Services linked to this product:

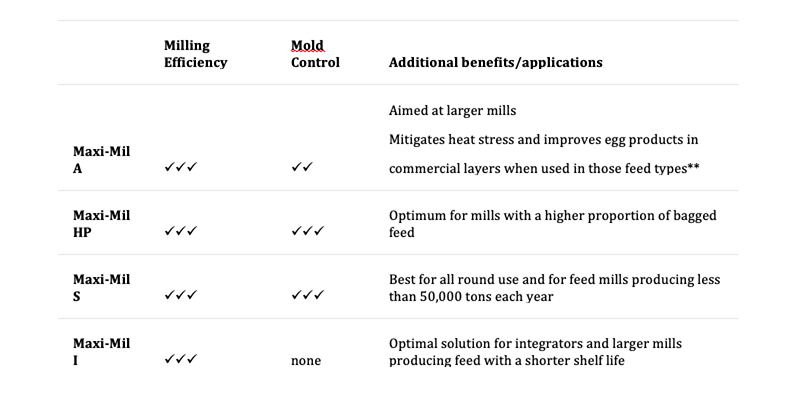

THE MAXI-MIL PRODUCT FAMILY

USING MAXI-MIL

Every mill is different. Every manufacturer has slightly different requirements. Every feed formulation varies in its ingredient mix. That’s why we have different Maxi-Mil products – and there’s a Maxi-Mil product to suit you.

EFFECTIVENESS

The addition of Maxi-Mil solution provides valuable benefits:

- increased moisture retention during cooling process

- improved conditioning: better moisture retention allows better thermal acceptance of the pellet press and more thorough heating of the meal particles, resulting in better gelatinization of starch, plasticization of proteins and softening of fiber

- reduced pellet mill energy requirement

- improved pellet stability and PDI index

- less fines

WHY FINES MATTER

High levels of fines are associated with poor live weight gain and FCR, in both wheat- and maize-based diets. Every 10% reduction in feed fines is worth up to $0.03 per bird* in live weight alone, ignoring the effect on FCR.

Kenny & Rollins, Aviagen 2007

INCORPORATING MAXI-MIL

To ensure you get the most from the Anitox Maxi-Mil Program, we’ve set up the Anitox Feed Milling Technology Team.

A member of our team will undertake a full assessment of your feed mill, its process and how the Maxi-Mil application can interface with your control systems to optimize application rates on each individual formulation. We’ll then continue to work with you to ensure you get the most out of Maxi-Mil.

By deploying the Maxi-Mil Program, you’ll be confident that you’re not only getting the most from your mill, but that you’re producing feed at optimum cost with the highest pellet quality. What’s more, you’re also assured of top-class customer service and ongoing technical support from the sector leader.

Your local Anitox Feed Milling Technologist is looking forward to helping you develop your own Maxi-Mil Program. Contact us to find out more.

HEAT STRESS IN LAYERS

Maxi-Mil A contains acetic acid, which has been shown to benefit layers during heat stress. Maxi-Mil A treated feed increases egg production and egg weight, while improving the quality of both shell and albumen.

Kadim et al, 2008